PERAR

Perar er en ledende italiensk produsent av kuleventilene API6D og API6A for en bred variasjon av applikasjoner i forskjellige sektorer slik som olje og gass, petrokjemisk, on- og offshore og tunge kjemikalier.

PERAR S.P.A er en av de første italienske produsentene av høykvalitets kuleventiler, og ble grunnlagt i 1962. Selskapet startet som en ledende leverandør innnen gassindustrien for markedet i Italia, og har i de påfølgende årene opplevd en kontinuerlig og jevn vekst i internasjonalt salg, produksjonskapasitet, effektivitet og teknologisk utvikling.

I dag er selskapet en ledende italiensk produsent av API6D og APi6A kuleventiler for et bredt spekter av applikasjoner, til ulike sektorer slik som olje og gass, petrokjemisk, onshore og offshore og tunge kjemikalier.

PERARs ingeniører jobber i flotte fasiliteter, som er utstyrt med de mest moderne CAD-systemene og PERAR søker også å utvikle CAM-systemet. Anlegget er utstyrt med Computerized Numeric Controlled Machine Tool Systems, styrt av høyt kvalifiserte teknikere og kontrollert av et datastyrt system. Sluttproduksjonen er kartlagt av kvalifiserte inspektører.

PERAR produserer kuleventiler i alle størrelser fra 1/2″ til 60″, ANSI-klasser 150 lbs til 2500 lbs API6D & API6A og API 2000 til API 20000 i karbonstål, rustfritt stål, tosidig stål, super dupleks stål, legeringsstål, incoloy-monel, 6mo, titanium med mer.

Konstruksjoner av kuleventiler som er tilgjengelige er: flytende type, trunnion mounted side entry, trunnion mounted top entry, metal seated, subsea og kryogen, bolted og full welded body.

PERAR kvalitetsikrer at hvert ledd i produksjonen er i samsvar med APIQ1, og alle prosessene er sertifisert etter ISO 9001. ISO 9001 setter også standarden for kvalitetssikringsprogrammet og for den interne organisasjonen fra ordreinngang til on time-levering av ventilene, sammen med nødvendig dokumentasjon og produktsertifisering, gjennom følgende trinn:

Ingeniørfag, design, materialvalg, produksjon, testing, levering, assistanse.

«PERARs strategiske visjon er rettet mot en konstant søken etter den beste løsningen for sine kunder, og etterstreber å sørge for et sunt og trygt arbeidsmiljø for sine ansatte og involverte tredjeparter. Visjonen deles fullt ut både internt i organisasjonen og av Perars kunder, leverandørerer og besøkende. Perar jobber for å oppnå målene innen kvalitet, miljø og arbeidsmiljøvern».

Produkter

Kuleventiler

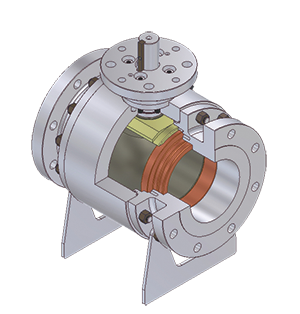

Floating Ball Valves

Standard Model FC

Standard Model FC:

2/ 3 pieces bolted body design.

API 6D, ISO 17292 design.

Full Bore and Reduced Bore design.

Flanged, Welding, Threaded Ends.

Anti blow‐out stem.

Anti static device.

Fire safe design.

Size: ½» to 6»

Pressure classes: ASME 150# to 2500#

Temperature range: -196C to 200C

Model FA

Model FA:

2/ 3 pieces threaded body.

ISO 17292 design.

Full Bore and Reduced Bore design.

Welding, Threaded Ends.

Anti blow‐out stem.

Anti static design.

Fire safe design.

Size: 1/4” to 4”

Pressure Classes: ASME 150# to 600#

ISO 17292 800#

3000, 6000 psi

Temperature Range: ‐196°C to 200°C

Model FI

Model FI:

3 pieces bolted body design with swing‐out body.

API 6D, ISO 17292 design.

Full Bore and Reduced Bore design.

Welding, Threaded Ends.

Anti blow‐out stem .

Anti static device.

Fire safe design.

Size: 1/2” to 2”

Pressure Classes: ASME 150# to 2500#

Temperature Range: ‐196°C to 200°C

Model TF (Top Entry)

Model TF (Top Entry)

1 piece bolted bonnet design.

Full in-line maintenance.

API 6D, ISO 17292 design.

Full Bore and Reduced Bore design.

Flanged, Welding, Threaded Ends.

Anti blow‐out stem.

Anti static device.

Fire safe design.

Size: 1/2” to 8”

Pressure Classes: ASME 150# to 1500#

Temperature Range: ‐196°C to 400°C

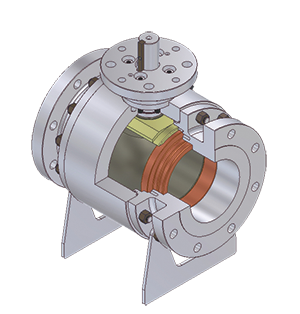

Compact Ball Valves

Standard Model

Standard Model:

API6A design.

Bi-directional sealing.

Spring loaded metal-to-metal seats.

End flange connection directly to the valve body.

Valve stem retained by shoulder on the body as anti-blow out design.

End flanges sized to withstand bending load up to 100% of pipe yield at full working pressure.

Fire testing to ISO 10497.

Compact design to save between 50% and 70% of valve weight if compared to standard ANSI valves.

Pressure Classes: 3750 psi

Size: 2” to 14”

Size: 16” to 30” Available on request (to be engineered)

Pressure Classes: 6250psi

Size: 2” to 12”

Size: 14” to 24” Available on request (to be engineered)

Pressure Classes: 10000psi

Size: 2” to 12” Available on request (to be engineered)

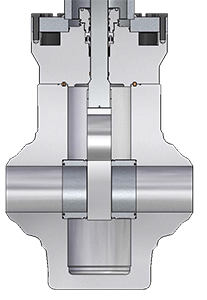

Compact Swing Check Model

Compact Swing Check Model:

API6A design.

Full opening design with optimized body profile to reduce flow turbulence

Spring loaded clapper.

Clapper-stem arrangement completely assembled inside the pressure boundary eliminating external leak path.

End flange connection directly to the valve body.

End flanges sized to withstand bending load up to 100% of pipe yield at full working pressure.

Fire testing to API6FD.

Compact design to save between 60% and 75% of valve weight if compared to standard ANSI valves.

Renewable seat.

3750 psi

Size: 2” to 14” ( Standard design)

Size: 16” to 24” (Available on request)

6250 psi

Size: 2” to 12” ( Standard design)

Size: 14” to 24” (Available on request)

10000 psi

Size: 2” to 12” ( Standard design)

15000 psi

Size: 2” to 8” (Available on request)

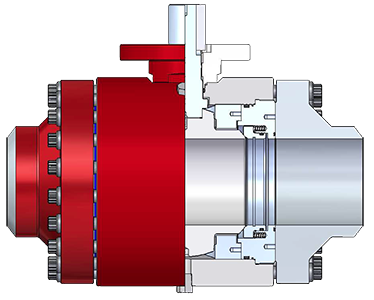

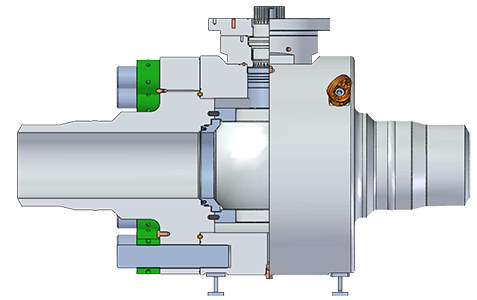

Split Body Side Entry Ball Valve

Standard Model

Standard Model:

API 6D, API 6A design.

Full Bore and Reduced Bore design.

Flanged or Welding Ends.

Spring loaded floating seats.

Bi‐directional sealing.

Anti blow‐out stem.

Anti static device.

Heavy duty bearings.

Double Block & Bleed design.

Fire safe design.

Size: 1/2” to 68»

Pressure Classes:

ASME 150# to 2500#

API 6A 3000 to 15000

Temperature Range: ‐196°C to 400°C

Split Body Side Entry Ball Valve

Standard Model

Standard Model:

API 6D, API 6A design.

Full Bore and Reduced Bore design.

Flanged or Welding Ends.

Spring loaded floating seats.

Bi‐directional sealing.

Anti blow‐out stem.

Anti static device.

Heavy duty bearings.

Double Block & Bleed design.

Fire safe design.

Size: 1/2” to 68»

Pressure Classes:

ASME 150# to 2500#

API 6A 3000 to 15000

Temperature Range: ‐196°C to 400°C

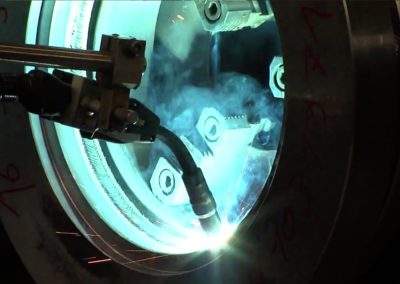

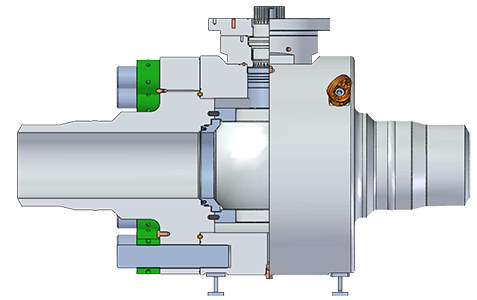

Fully Welded Body Trunnion

Mounted Side Entry Ball Valve

Standard Model

Standard Model:

API 6D, API 6A design.

Full Bore and Reduced Bore design.

Flanged or Welding Ends.

Spring loaded floating seats.

Bi‐directional sealing.

Anti blow‐out stem.

Anti static device.

Heavy duty bearings.

Double Block & Bleed design.

Fire safe design

Size: 1/2” to 68”

Pressure Classes: ASME 150# to 2500#

Temperature Range: ‐196°C to 400°C

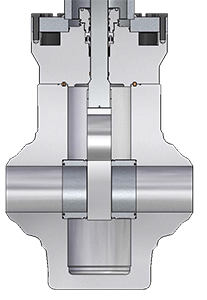

Top Entry Ball Valve

About

API6DSS, API6A, API17D design as requested.

Bi-directional sealing.

Spring loaded metal-to-metal seats (tungsten carbide coating 0,2 mm – 0,4 mm thickness).

Anti-blow out design stem.

Non-elastomeric seals to avoid the risk of gradual degradation of the seals over their lifetime.

Full metal-to-metal sealing at body-bonnet and valve stem.

Forged material to comply with API6A PSL3.

Valve actuation with dedicated hydraulic actuator and ROV operable Gearbox (fixed or retrievable).

Forged Body (PSL3-PSL4)

Forged Body (PSL3-PSL4)

Pressure Classes: 3000 psi /900-1500 lbs

Size: 1/2” to 36”

Pressure Classes: 5000 psi / 2500 lbs

Size: 1/2” to 30”

Pressure Classes: 7500 psi

Size: 1/2” to 22”

Pressure Classes: 10000 psi

Size: 1/2” to 9”

Pressure Classes: 15000 psi

Size: 1/2” to 9”

Cast Body (PSL2)

Cast Body (PSL2)

Pressure Classes: 3000 psi /900-1500 lbs

Size: 4” to 48”

Pressure Classes: 5000 psi / 2500 lbs

Size: 4” to 30”

Pressure Classes: 7500 psi

Size: 4” to 22”

Pressure Classes: 10000 psi

Size: 4” to 9”

Top Entry Ball Valve

About

API6DSS, API6A, API17D design as requested.

Bi-directional sealing.

Spring loaded metal-to-metal seats (tungsten carbide coating 0,2 mm – 0,4 mm thickness).

Anti-blow out design stem.

Non-elastomeric seals to avoid the risk of gradual degradation of the seals over their lifetime.

Full metal-to-metal sealing at body-bonnet and valve stem.

Forged material to comply with API6A PSL3.

Valve actuation with dedicated hydraulic actuator and ROV operable Gearbox (fixed or retrievable).

Forged Body (PSL3-PSL4)

Forged Body (PSL3-PSL4)

Pressure Classes: 3000 psi /900-1500 lbs

Size: 1/2” to 36”

Pressure Classes: 5000 psi / 2500 lbs

Size: 1/2” to 30”

Pressure Classes: 7500 psi

Size: 1/2” to 22”

Pressure Classes: 10000 psi

Size: 1/2” to 9”

Pressure Classes: 15000 psi

Size: 1/2” to 9”

Cast Body (PSL2)

Cast Body (PSL2)

Pressure Classes: 3000 psi /900-1500 lbs

Size: 4” to 48”

Pressure Classes: 5000 psi / 2500 lbs

Size: 4” to 30”

Pressure Classes: 7500 psi

Size: 4” to 22”

Pressure Classes: 10000 psi

Size: 4” to 9”

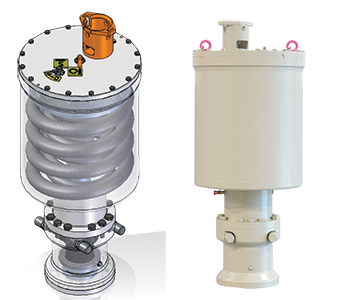

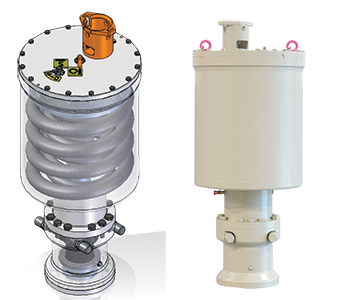

Cryogenic Ball Valves

Standard Model

Standard Model:

API 6D, API 6A design

Full Bore and Reduced Bore design.

Flanged or Welding Ends.

Spring loaded floating seats.

Bi‐directional sealing.

Anti blow‐out stem.

Anti static device.

Heavy duty bearings.

Double Block & Bleed design.

Fire safe design.

Low temperature carbon steel, stainless steel.

Size: 1/2″ to 60″

Pressure Classes: ANSI 150-300-600-900-1500-2500

API 2000-3000-5000-10000-15000

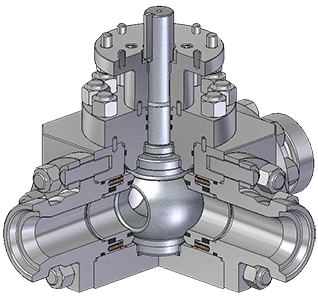

Three Way Ball Valves

Standard Model

API6D, ASME B16.34 or API6A design.

Spring loaded metal-to-metal seats.

Anti blow-out design.

Flow plans for T and L ports.

Fire testing to API6FA.

Pressure Classes: 3750 psi

Size (Standard design): 2” 2 ½” 3” 4” 5” 6” 8” 10” 12” 14” 16”-24”

Size (Available on request): 16”-24”

Pressure Classes: 6250 psi

Size (Standard design): 2” 2 ½” 3” 4” 5” 6” 8” 10” 12”

Size (Available on request): 14” 16”-24”

Pressure Classes: 10000 psi

Size (Standard design): 2” 2 ½” 3” 4” 5” 6” 8” 10” 12”

Pressure Classes: 15000 psi

Size (Available on request): 2” 2 ½” 3” 4” 5” 6” 8”

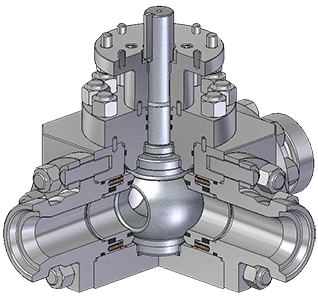

Three Way Ball Valves

Standard Model

API6D, ASME B16.34 or API6A design.

Spring loaded metal-to-metal seats.

Anti blow-out design.

Flow plans for T and L ports.

Fire testing to API6FA.

Pressure Classes: 3750 psi

Size (Standard design): 2” 2 ½” 3” 4” 5” 6” 8” 10” 12” 14” 16”-24”

Size (Available on request): 16”-24”

Pressure Classes: 6250 psi

Size (Standard design): 2” 2 ½” 3” 4” 5” 6” 8” 10” 12”

Size (Available on request): 14” 16”-24”

Pressure Classes: 10000 psi

Size (Standard design): 2” 2 ½” 3” 4” 5” 6” 8” 10” 12”

Pressure Classes: 15000 psi

Size (Available on request): 2” 2 ½” 3” 4” 5” 6” 8”

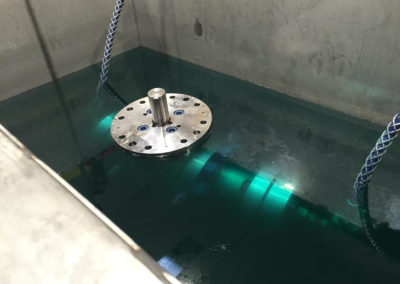

Subsea Ventiler

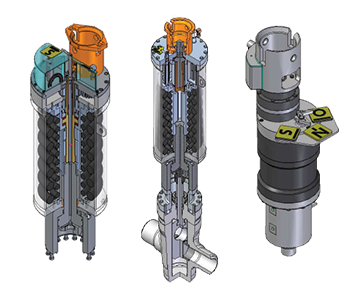

Subsea Top Entry Ball Valves

About

API6DSS, API6A, API17D design as requested.

Bi-directional sealing.

Spring loaded metal-to-metal seats (tungsten carbide coating 0,2 mm – 0,4 mm thickness).

Anti-blow out design stem.

Non-elastomeric seals to avoid the risk of gradual degradation of the seals over their lifetime.

Full metal-to-metal sealing at body-bonnet and valve stem.

Forged material to comply with API6A PSL3.

Valve actuation with dedicated hydraulic actuator and ROV operable Gearbox (fixed or retrievable).

Forged Body (PSL3-PSL4)

Forged Body (PSL3-PSL4)

Pressure Classes: 3000 psi /900-1500 lbs

Size: 1/2” to 36”

Pressure Classes: 5000 psi / 2500 lbs

Size: 1/2” to 30”

Pressure Classes: 7500 psi

Size: 1/2” to 22”

Pressure Classes: 10000 psi

Size: 1/2” to 9”

Pressure Classes: 15000 psi

Size: 1/2” to 9”

Cast Body (PSL2)

Cast Body (PSL2)

Pressure Classes: 3000 psi /900-1500 lbs

Size: 4” to 48”

Pressure Classes: 5000 psi / 2500 lbs

Size: 4” to 30”

Pressure Classes: 7500 psi

Size: 4” to 22”

Pressure Classes: 10000 psi

Size: 4” to 9”

Subsea Side Entry Ball Valves

Standard Model

API6DSS, API6A, API17D design as requested.

Bi-directional sealing.

Spring loaded metal-to-metal seats (tungsten carbide coating 0,2 mm – 0,4 mm thickness).

Anti-blow out design stem.

Non-elastomeric seals to avoid the risk of gradual degradation of the seals over their lifetime.

Full metal-to-metal sealing at any primary pressure boundary including valve stem.

Forged material to comply with API6A PSL3.

Valve actuation with dedicated hydraulic actuator and ROV operable Gearbox (fixed or retrievable).

Pressure Classes: 3000 psi /900-1500 lbs

Size: 1/2” to 48”

Pressure Classes: 5000 psi / 2500 lbs

Size: 1/2” to 30”

Pressure Classes: 7500 psi

Size: 1/2” to 22”

Pressure Classes: 10000 psi

Size: 1/2” to 12”

Pressure Classes: 15000 psi

Size: 1/2” to 12”

Subsea Side Entry Ball Valves

Standard Model

API6DSS, API6A, API17D design as requested.

Bi-directional sealing.

Spring loaded metal-to-metal seats (tungsten carbide coating 0,2 mm – 0,4 mm thickness).

Anti-blow out design stem.

Non-elastomeric seals to avoid the risk of gradual degradation of the seals over their lifetime.

Full metal-to-metal sealing at any primary pressure boundary including valve stem.

Forged material to comply with API6A PSL3.

Valve actuation with dedicated hydraulic actuator and ROV operable Gearbox (fixed or retrievable).

Pressure Classes: 3000 psi /900-1500 lbs

Size: 1/2” to 48”

Pressure Classes: 5000 psi / 2500 lbs

Size: 1/2” to 30”

Pressure Classes: 7500 psi

Size: 1/2” to 22”

Pressure Classes: 10000 psi

Size: 1/2” to 12”

Pressure Classes: 15000 psi

Size: 1/2” to 12”

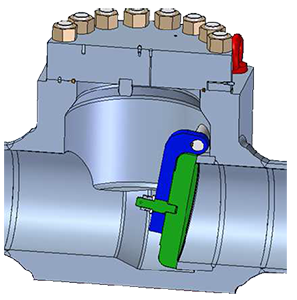

Subsea Swing Check Valves

About

API6DSS, API6A, API17D design as requested.

Bi-directional pigging.

Metal-to-metal seats (3mm hardfacing with Stellite 6 or Inconel 625).

ROV lock open stem design to keep valve fully open for reverse pigging.

Non-elastomeric seals to avoid the risk of gradual degradation of the seals over their lifetime.

Full metal-to-metal sealing at body-bonnet.

Seat integral to valve body and with slope to engage the seat-to-disc sealing at low pressure.

Forged material to comply with API6A PSL3Valve actuation with dedicated hydraulic actuator or ROV operable devices

Forged Body (PSL3-PSL4)

Forged Body (PSL3-PSL4)

Pressure Classes: 3000 psi /900-1500 lbs

Size: 1/2” to 36”

Pressure Classes: 5000 psi / 2500 lbs

Size: 1/2” to 30”

Pressure Classes: 7500 psi

Size: 1/2” to 22”

Pressure Classes: 10000 psi

Size: 1/2” to 9”

Pressure Classes: 15000 psi

Size: 1/2” to 9”

Cast Body (PSL2)

Cast Body (PSL2)

Pressure Classes: 3000 psi /900-1500 lbs

Size: 4” to 48”

Pressure Classes: 5000 psi / 2500 lbs

Size: 4” to 30”

Pressure Classes: 7500 psi

Size: 4” to 22”

Pressure Classes: 10000 psi

Size: 4” to 9”

TC Slabs Gate Valves

Standard Model

API6DSS, API6A, API17D design as requested.

Bi-directional sealing.

Floating spring energized metal-to-metal seats (tungsten carbide coating thickness 0,25 mm on seats and 0,4 mm on gate).

Non-elastomeric seals to avoid the risk of gradual degradation of the seals over their lifetime.

Full metal-to-metal sealing at any primary pressure boundary including valve stem at fail position with the option of double backseat to provide metal sealing at both open and close positions.

Downstream sealing with pressurized body cavity to assist fail safe stroke.

Forged material to comply with API6A PSL3.

Valve actuation with dedicated hydraulic actuator and ROV operable Gearbox.

Pressure Classes: 3000 psi /900-1500 lbs

Size: 1/2” to 1” 1.13/16” 1/16” 1/8” 4 1/16” 5 1/8” 7 1/16” 9” 11” 13 5/8”

Pressure Classes: 5000 psi / 2500 lbs

Size: 1/2” to 1” 1.13/16” 1/16” 1/8” 4 1/16” 5 1/8” 7 1/16” 9” 11” 13 5/8”

Pressure Classes: 7500 psi

Size: 1/2” to 1” 1.13/16” 1/16” 1/8” 4 1/16” 5 1/8” 7 1/16” 9” 11” 13 5/8”

Pressure Classes: 10000 psi

Size: 1/2” to 1” 1.13/16” 1/16” 1/8” 4 1/16” 5 1/8” 7 1/16” 9” 11” 13 5/8”

Pressure Classes: 15000 psi

Size: 1/2” to 1” 1.13/16” 1/16” 1/8” 4 1/16” 5 1/8”

TC Slabs Gate Valves

Standard Model

API6DSS, API6A, API17D design as requested.

Bi-directional sealing.

Floating spring energized metal-to-metal seats (tungsten carbide coating thickness 0,25 mm on seats and 0,4 mm on gate).

Non-elastomeric seals to avoid the risk of gradual degradation of the seals over their lifetime.

Full metal-to-metal sealing at any primary pressure boundary including valve stem at fail position with the option of double backseat to provide metal sealing at both open and close positions.

Downstream sealing with pressurized body cavity to assist fail safe stroke.

Forged material to comply with API6A PSL3.

Valve actuation with dedicated hydraulic actuator and ROV operable Gearbox.

Pressure Classes: 3000 psi /900-1500 lbs

Size: 1/2” to 1” 1.13/16” 1/16” 1/8” 4 1/16” 5 1/8” 7 1/16” 9” 11” 13 5/8”

Pressure Classes: 5000 psi / 2500 lbs

Size: 1/2” to 1” 1.13/16” 1/16” 1/8” 4 1/16” 5 1/8” 7 1/16” 9” 11” 13 5/8”

Pressure Classes: 7500 psi

Size: 1/2” to 1” 1.13/16” 1/16” 1/8” 4 1/16” 5 1/8” 7 1/16” 9” 11” 13 5/8”

Pressure Classes: 10000 psi

Size: 1/2” to 1” 1.13/16” 1/16” 1/8” 4 1/16” 5 1/8” 7 1/16” 9” 11” 13 5/8”

Pressure Classes: 15000 psi

Size: 1/2” to 1” 1.13/16” 1/16” 1/8” 4 1/16” 5 1/8”

Subsea Aktuator

Subsea Linear Hydraulic

Actuators

About

API17D design as requested.

All models available double acting (DA) and spring return (FSC or FSO).

Hydraulic system assembled in clean environment (ISO8 clean room) and flushed to SAE AS4059 6B-F.

Visual and remote (continuous or limit switches) position indicator.

Balanced pressure cavities with local open or close compensation systems or common sea chest.

Linear DA

Linear DA

10 – 50 kN

50 – 100 kN

100 – 250 kN

250 – 500 kN

500 – 1000 kN

750 -1500 kN

Linear FSC/FSO

Linear FSC/FSO

10 – 50 kN

50 – 100 kN

100 – 250 kN

250 – 500 kN

500 – 1000 kN

Linear Mechanical

Linear Mechanical

10 – 50 kN

50 – 100 kN

100 – 250 kN

250 – 500 kN

500 – 1000 kN

750 -1500 kN

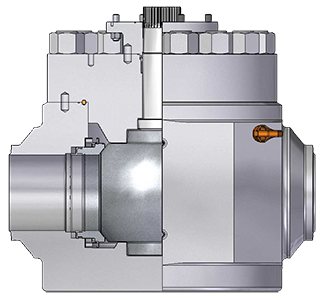

Subsea Quarter Turn Actuators

About

API17D design as requested.

All models available double acting (FAI) and spring return (FSC or FSO).

Range of mechanical or hydraulic override and indicator mechanisms.

Hydraulic system assembled in clean environment (ISO8 clean room) and flushed to SAE AS4059 6B-F.

Diver or ROV retrievable with provision of a connecting clutch system.

Visual and remote (continuous or limit switches) position indicator.

Balanced pressure cavities with open or close compensation systems.

R&P FAI

R&P FAI

1000-15000 Nm

20 – 70 kNm

50 – 150 kNm

150 – 200 kNm

200 – 500 kNm

R&P FSC/FSO

R&P FSC/FSO

1000-15000 Nm

20 – 70 kNm

50 – 150 kNm

150 – 200 kNm

HS FAI

HS FAI

1000-15000 Nm

20 – 70 kNm

50 – 150 kNm

150 – 200 kNm

200 – 500 kNm

HS FSC/FSO

HS FSC/FSO

1000-15000 Nm

20 – 70 kNm

50 – 150 kNm

150 – 200 kNm

Subsea Quarter Turn Actuators

About

API17D design as requested.

All models available double acting (FAI) and spring return (FSC or FSO).

Range of mechanical or hydraulic override and indicator mechanisms.

Hydraulic system assembled in clean environment (ISO8 clean room) and flushed to SAE AS4059 6B-F.

Diver or ROV retrievable with provision of a connecting clutch system.

Visual and remote (continuous or limit switches) position indicator.

Balanced pressure cavities with open or close compensation systems.

R&P FAI

R&P FAI

1000-15000 Nm

20 – 70 kNm

50 – 150 kNm

150 – 200 kNm

200 – 500 kNm

R&P FSC/FSO

R&P FSC/FSO

1000-15000 Nm

20 – 70 kNm

50 – 150 kNm

150 – 200 kNm

HS FAI

HS FAI

1000-15000 Nm

20 – 70 kNm

50 – 150 kNm

150 – 200 kNm

200 – 500 kNm

HS FSC/FSO

HS FSC/FSO

1000-15000 Nm

20 – 70 kNm

50 – 150 kNm

150 – 200 kNm

Ring oss

(+47) 959 42 660

(+47) 906 81 910

Adresse

Jegerstien 2A, 6523 Frei, Norge